History Of Concurrent Engineering

Benefits Of Concurrent Engineering

Organisations are continuously pressured to launch new products and services to gain competitive advantage and satisfy highly demanding global market. And most of this pressure is directed towards product development teams, where majority of organisations still follow traditional or so called stage-gate processes. Although stage-gate process works, it is not flexible enough and tends to constrain creativity and innovation. One paradigm that can help you bridge this gap and is becoming increasingly more popular (particularly in the last 5 to 6 years) is called Set-Based Concurrent Engineering or shorter SBCE. WHAT IS SET-BASED CONCURRENT ENGINEERING? Set-Based Concurrent Engineering is a product development approach which offers an environment that not only permits but encourages radical innovation, increased learning and reuse of knowledge, reduces the development risk, and enable shorter and less costly development cycles.

One of the most common definitions amongst practitioners is that SBCE is an approach where multifunctional team(s) ideates, develops and communicates sets of conceptual solutions in parallel. As the solutions progress, team(s) builds-up the understanding, knowledge and evidence about the sets, which permits them to gradually narrow these sets by eliminating inferior or/and infeasible solutions. As they narrow, teams commit to staying within the sets so that others can rely on them. This definition is depicted in the below image, where each bubble represent a different subsystem set of concepts. Visual representation of the SBCE (convergence) process across different subsystems While the image above displays the convergence process of different subsystems, similar approach can be adopted for conceptual solutions within each subsystem set. The schematic below shows how an initial set of ideas is developed, screened, and converged through time, based on the knowledge gained. Visual representation of an SBCE within a single subsystem Critical design/technical decisions are purposely delayed until the last possible moment to ensure that customer expectations are fully understood and that the reached design meets the success criteria.

Examples Of Concurrent Engineering

THE EVOLUTION OF SET-BASED CONCURRENT ENGINEERING In 1995 research group from MIT described the Toyota’s product development system and how they practice it. They named it Set-Based Concurrent Engineering (Ward et al., 1995).

A year later, they described a set of 11 principles (Sobek & Ward, 1996) and have in 1999 refined and categorised them in a framework of three broad principles based on Toyota’s best practices, each with three different steps to implementing them (Sobek, et al, 1999). This framework is considered as the foundation of most SBCE research and implementation project. Matic Golob is a Senior Research Program Manager, trainer, and coach at Lean Analytics Association (LAA) where he focuses on the development, introduction and implementation of bespoke lean innovation and new product development solutions to support organizations on their continuous improvement journeys. He specializes in Set-Based Integrated Innovation, Design Thinking, Human-Cantered Design, SBCE, Visual Management, Knowledge Management, Training Development and Gamified Learning. Matic previously worked as a Research Fellow and Project Manager at Cranfield University, where he was a task leader of Set-Based Design activities for the British aerospace project named ‘Configuration Optimization of Next Generation Aircraft’. Throughout his career, Matic collaborated with multinational organizations from aerospace, construction, and the fast moving consumer goods industry to introduce and implement lean thinking into their existing innovation and product development processes. He completed his master degree in Global Product Development and Management from Cranfield University in 2012.

Matic is also a co-author of several journal and conference publications, as well as a regular speaker at lean and product development events, and he is currently co-developing his first book about lean product development best practices.

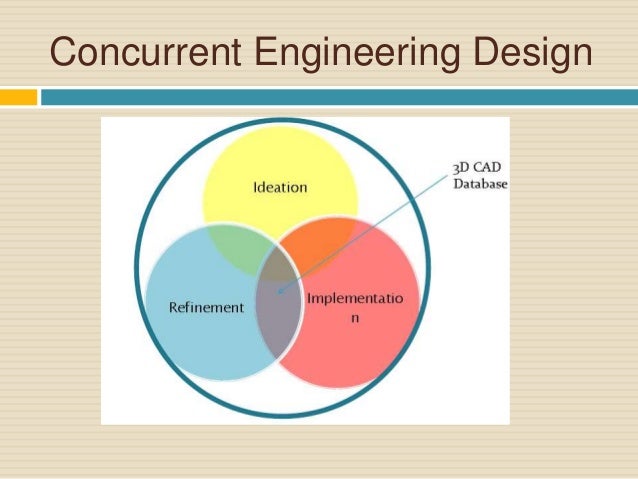

Concurrent Engineering vs Traditional Approach A comparison of the concurrent engineering model and the traditional model of product realization is shown in. As it can be seen, there are huge time savings when concurrent engineering is implemented in the design-to-manufacturing cycle of the product realization. Also the concurrent engineering method does not lead into problems of implementing the design in manufacturing such as costly engineering changes. This will result in reducing the overall product cost. In the, once the design is made, all of the departments that are invilved in the product realization are expected to follow it although they have very little input in the design of the product. A frequently asked question is, how good the design can be without involvment of domain experts? Very often, the design team in the traditional model, do not have the knowledge and the skills to make a product that will be functional, of high quality and manufacturable.

After the design team completes its task, the production processes are designed based on the design of the product. Therefore, if the product is poorly designed, the ensuing processes will be poorly designed, too. For example, if the manufacturing department has a part, that is difficult to manufacture due to the poor design, considerable time will be expended in order to manufacture the part. To accomplish this, sometimes, the manufacturing department introduces changes to the original design such as either updating the part tolerances or changing the number of parts in the design. At the same time, the changes in the product design may not be either communicated to others in the product realization process or too late to prevent decisions that are based on the original product design. At any rate the traditional model is vulnerable to a costly and error prone product realization. Figure 5 shows that while the CE design method begins with a cost target for the product, the traditional method has no such benchmark.

Following the design stage, the CE team compares the derived cost of the product design to the targeted cost. Only if the estimated cost is lower or equal to the targeted cost, the production of the product can begin. Such design discipline is essential to ensure that the price of the product is competitive in the market. It is obvious that by following the CE model all the disadvantages of the traditional model can be avoided. The difference in the two approaches will be more evident upon study of the overall production cost in the product's life cycle.